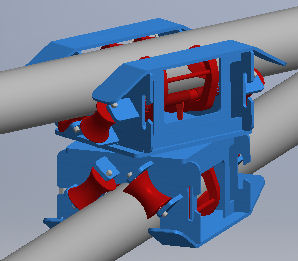

Subsea Pipe Crossing

Subsea Pipe Crossings match any pipe size, bare and coated. A common central Pivot Pin provides a common interface between all sizes, bare or coated. Additionally the Pivot Pin allows the unit to swivel to match the angle of the pipelines. Thus the operator can mix and match the two halves of the Pipe Crossing to match any pipeline combination. A size is set to handle coating thickness up to 2% of the diameter of the pipe. Thus for thicker coatings, use the next larger size adjusted to fit by thicker rollers

SUBSEA PIPE CROSSING

Click on image for more information

SUBSEA PIPE CROSSING PROVIDES PERMANENT SEPARATION FOR SUBSEA PIPELINES

LOCKS ONTO 2 CROSSING PIPELINES

PROVIDES ROLLERS FOR FREE MOVEMENT OF PIPELINES

INSULATES BETWEEN PIPELINES

PROVIDES DESIGNATED SHEARING FORCE

ELIMINATES REPETITIVE SANDBAGGING

CAN MIX AND MATCH SIZES (I.E. 10” X 6”)