PIPELINE REMEDIATION PRODUCTS

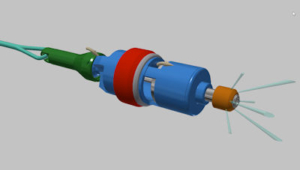

WIRE ROPE PIG, WRP-3

PIPELINE CLEANING WHILE PRODUCTION IS FLOWING

- Released into the flow and cleans the pipeline as it moves in the direction of the flow and on the return trip.

- With production stopped, it is pumped into the pipeline.

- Click here for movie of 2/3s scale 6″ pig in lab testing using available shop air as media.

Patent and patent pending

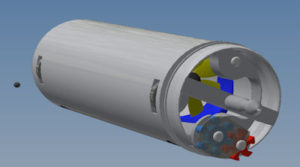

FERAL PIG

PIPELINE CLEANING WHILE PRODUCTION IS FLOWING.

Long term pipeline remediation by a cleaning pig which is resident in the pipeline, until you tell it to return to the starting.

Continually cleans between two movable trip points.

Self powered using pipeline flow, does not interfere with pipeline flow.

Patented

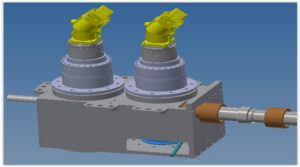

SYNTHETIC ROPE WINCH

PIPELINE CLEANING WHILE PRODUCTION IS FLOWING.

Utility winch for handling synthetic rope and similar products.

Eliminates the need for back tension on the storage spool or reel.

40,000# capacity and 50 feet per minute speeds (other sizes are available)

Patented

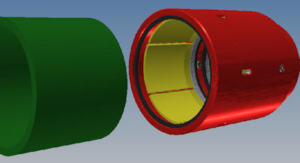

BETA-LOK PIPELINE CONNECTOR

Rapid make-up for offshore pipelay operations. Fully preloaded metal sealing on bare pipe.

Set, internal test, and external test in 2 minutes.

Patented

BETA PIPE CROSS

Easy to install pipeline separator which isolates sub sea pipelines, and moves with them when the pipelines move.

Fast. Installed when pipelines are laid.

Patented.

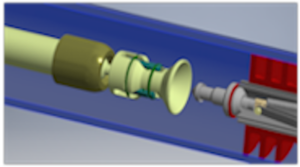

BETA CTU LATCH

Spring loaded to remain on centerline and engage a pig in a pipeline.

Will retrieve the pig through a 5D bend.

Patented.

Crawford Technical Services and Beta Subsea Systems

Providing subsea pipeline remediation equipment, services and IP to the industry. The items indicated by the linked icons above are available as equipment or IP for licensing. In addition we develop new concepts and product, resulting in greater profitability for your company.

Subsea pipelines have wax in the oil plate out onto the bore of some pipelines, causing a restriction in the pipelines. This restriction reduces the pipe flow, and therefore the income from the pipelines. Over time the buildup increases until the bore can become completely blocked. This provides a special pipeline remediation challenge, as flow in the pipeline is blocked.

In other pipelines transporting primarily gas, water and gas can form hydrates, resulting in a type of crushed ice structure. When the hydrates form they can quickly block the pipeline, completely blocking the pipeline. Hydrates can take months to naturally melt, resulting is major pipeline losses. Some of our tools address this problem.

We provide equipment for both flow restricted and blocked pipelines due to either wax or hydrates and with production flowing or stopped.

Oilfield product development captured in specific products as illustrated the icons shown above. Providing offshore equipment, services, and intellectual property. Also, developing new concepts and products, due to a wide range of experiences. Click on the icons to receive more information.